AAC Blocks

- Home

- /

- AAC Blocks

ONECRETE

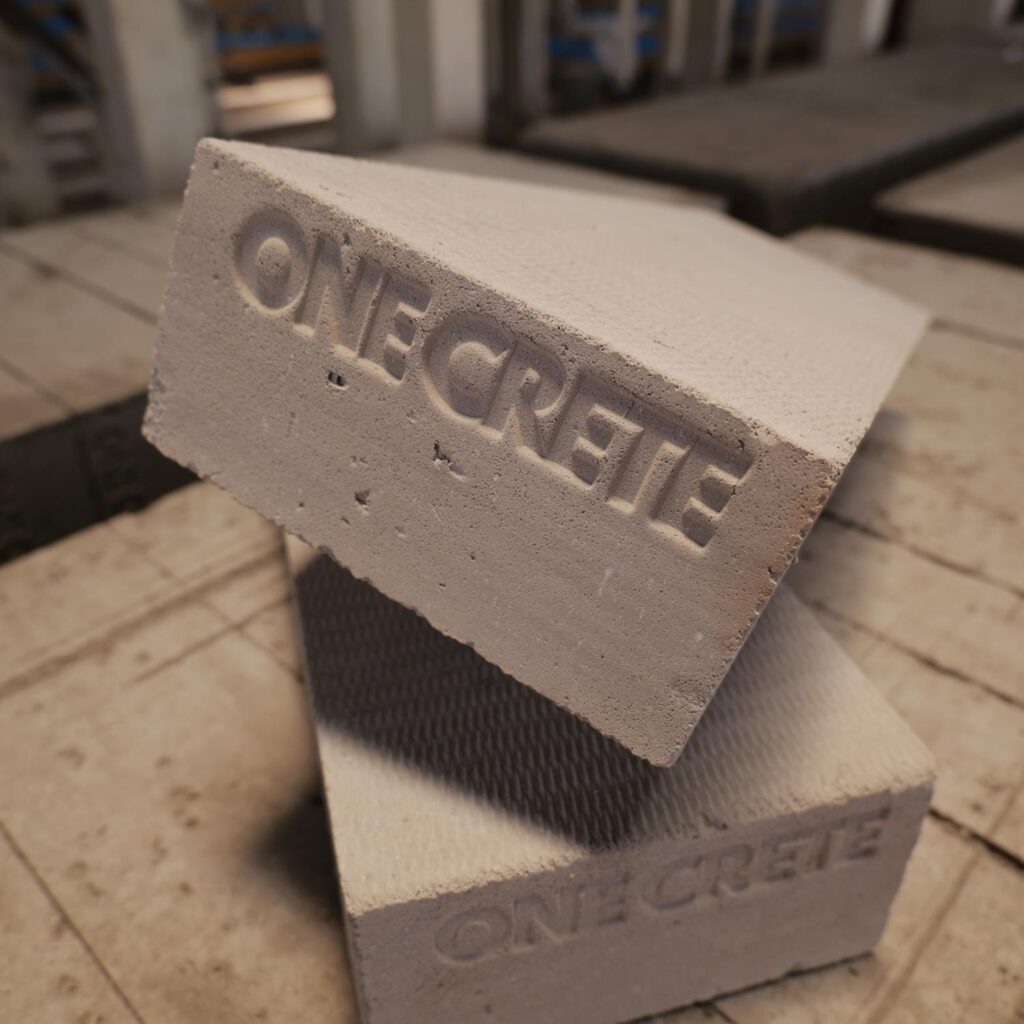

Why Choose ONECRETE AAC Blocks?

At ONECRETE, we manufacture high-quality AAC (Autoclaved Aerated Concrete) blocks, designed to revolutionize modern construction. Our blocks are lightweight, strong, energy-efficient, and environmentally friendly, making them the ideal choice for residential, commercial and industrial projects across Tamil Nadu and Kerala.

The ONECRETE Advantages

Lightweight Yet Strong

3X lighter than conventional bricks, ONECRETE AAC blocks reduce the overall load on a building, making them easier to handle, transport, and install—without compromising strength.

Superior Thermal Insulation

With a high R-value, ONECRETE AAC blocks keep buildings cooler in summer and warmer in winter, reducing the need for excessive air conditioning or heating. This leads to energy savings and lower electricity bills.

Fire Resistant (Up to 4 Hours)

Our blocks provide exceptional fire resistance—withstanding up to 4 hours of fire exposure as per international safety standards. This makes them ideal for fire-prone areas and ensures enhanced safety for homes and buildings.

Soundproof & Noise Reduction

The microcellular structure of ONECRETE AAC blocks absorbs sound waves, reducing noise pollution and ensuring a quieter indoor environment—perfect for homes, schools, hospitals, and offices.

Eco-Friendly & Sustainable

ONECRETE AAC blocks are manufactured using natural, non-toxic materials with a 60% lower carbon footprint compared to traditional bricks. They also contribute to LEED & Green Building certifications, making them a sustainable choice for modern construction.

Precision-Cut for Easy Installation

Our advanced manufacturing process ensures dimensional accuracy, leading to seamless construction with minimal wastage. This means less mortar usage, faster construction times, and reduced labour costs.

Earthquake & Impact Resistant

Due to their lower density and high shock absorption, ONECRETE AAC blocks provide better stability during seismic activity, making them ideal for earthquake-prone regions.

Water & Moisture Resistance

ONECRETE AAC blocks have a non-porous surface, preventing water absorption and dampness issues. This makes them highly suitable for coastal and high-humidity areas.

Easy to Work With

Our AAC blocks can be cut, drilled, and shaped effortlessly, simplifying construction and allowing architects and engineers greater flexibility in design.

Construction Advices

Built for the Future of Construction

By choosing ONECRETE AAC blocks, you’re investing in a stronger, smarter, and more sustainable building solution. Whether for residential homes, commercial buildings, or large-scale infrastructure projects, our blocks provide superior performance, long-term durability, and cost-effective construction.

Contact Us Today

To learn more or get a customized quote for your project!

ONECRETE

AAC Blocks

01

Dimensions

| Sizes L x H x W | Volume CBM | No of Blocks (Per CBM) | Face Area (Per Block in Sq.Ft) |

|---|---|---|---|

| 600 x 200 x 100 | 0.012 | 83.33 | 1.32 |

| 600 x 200 x 150 | 0.018 | 55.56 | 1.32 |

| 600 x 200 x 200 | 0.024 | 41.67 | 1.32 |

| 600 x 200 x 225 | 0.027 | 36.23 | 1.32 |

02

Costing

| Parameter | AAC Block | Clay Brick |

|---|---|---|

| Total cost in construction of 10'X10' wall (Inclusive of raw material& plastering cost) | Rs. 6,600/- | Rs. 12,000/- |

| Total Saving in 10'X10' wall | Rs. 5,400/- | NIL |

| No. of Blocks/Bricks per cubic metre | 80 Blocks/Cum (625x200x100mm) | 525 Bricks/Cum (225×75×100mm) |

| Total cost of Blocks/Bricks in construction of 10'X10' wall | 74 Blocks of (625X200X100mm) | 525 Bricks (225X75X100mm) |

| Price per blocks in 10'X10' construction | Rs. 55/- per block | - |

| Cost of block converted in to size of bricks vs per brick cost | Rs. 7.5 per brick | Rs. 11 per brick |

| Mortar cost per 100sft. | Rs. 900/- | Rs. 1750/- |

| Plaster | Only one side mandatory (other side direct gypsum plaster) | Both sides are Mandatory |

03

Comparison

| Parameter | AAC Block | Clay Brick |

|---|---|---|

| Structural Cost | Steel saving upto 15% | No saving |

| Cement Mortar for Plaster & Masonry | Required Less due to flat, even surface and less number of joints | Requires more due to Irregular surface and more number of joints |

| Breakage | Less than 2% | Average 10 to 12% |

| Construction Speed | Speedy construction due to its big size light weight and easy to cut in any size or shape | Comparatively slow |

| Quality | Uniform & Consistent | Normally varies |

| Fitting & Chasing | All kind of fitting and chasing possible | All kind of fitting and chasing possible |

| Carpet Area | More due to less thickness of walling material | Comparatively Less |

| Energy Saving | Approx. 30% reduction in air-conditioned Load | No such saving |

| Chemical Composition | Flyash used around: 65 to 68% which reacts with lime and cement to form AAC | Soil used contains many inorganic Impurities like sulphate etc. resulting in efflorescence |